Transform Your Workflow with Advanced Laser Cleaning Metal Solutions

In modern manufacturing and industrial maintenance, keeping metal surfaces clean and free of rust, paint, or other contaminants is crucial for efficiency and quality. Traditional cleaning methods such as sandblasting or chemical treatments often involve high costs, extensive labor, and environmental concerns. This is where laser cleaning metal technology emerges as a game-changer, offering precision, speed, and eco-friendly solutions.

What is Laser Cleaning Metal?

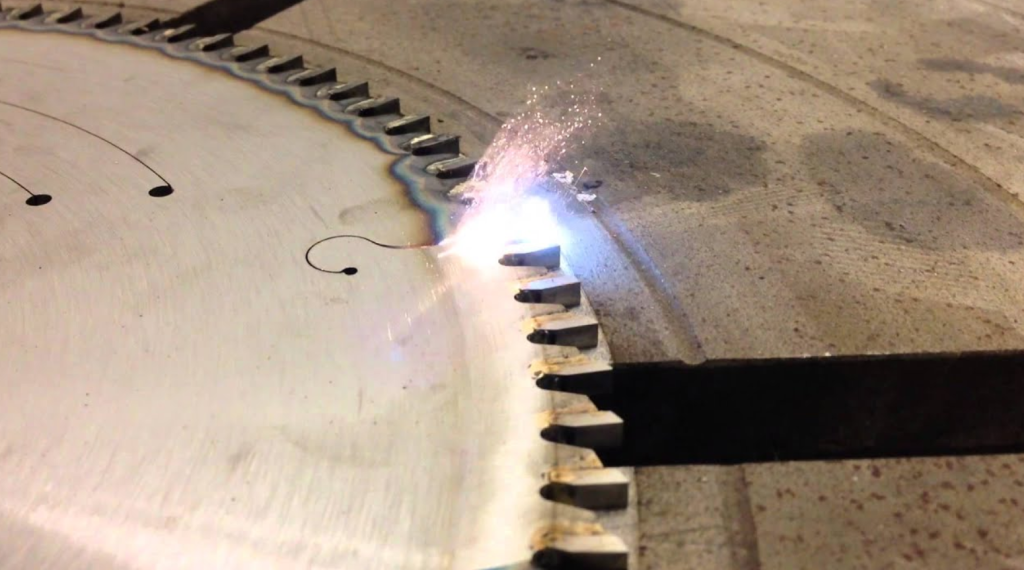

Laser cleaning metal is a state-of-the-art technique that uses focused laser beams to remove unwanted materials from a metal surface without causing damage to the underlying substrate. Unlike conventional methods, it does not rely on chemicals or abrasive tools, making it safer for operators and the environment. The process is fast, precise, and can be automated for large-scale production lines.

Advantages of Laser Cleaning

For industries dealing with metal fabrication, automotive parts, or heavy machinery, laser cleaning provides a host of benefits. It ensures thorough removal of rust, paint, oils, or residues while preserving the integrity of the metal. Maintenance becomes simpler and less time-consuming, production lines operate more efficiently, and overall operational costs decrease. Additionally, laser cleaning minimizes waste, making it a sustainable alternative for environmentally-conscious businesses.

Why Choose Mart Laser?

Mart Laser has been at the forefront of providing cutting-edge laser cleaning solutions. With years of experience in industrial laser technology, the company specializes in delivering equipment designed for precision, reliability, and scalability. Whether it’s small-scale workshops or large manufacturing plants, Mart Laser’s systems can be tailored to meet specific operational requirements. Their machines are user-friendly, energy-efficient, and backed by expert technical support.

Applications Across Industries

The versatility of laser cleaning makes it suitable for multiple industries. Automotive manufacturers can remove rust and coatings from parts efficiently. Aerospace and defense sectors benefit from high-precision cleaning for sensitive components. Metal fabrication shops can achieve surface preparation before welding or painting without the risk of damaging the materials. Even restoration projects, such as cleaning historical artifacts or sculptures, benefit from the non-invasive nature of laser cleaning metal.

Conclusion

Adopting laser cleaning metal technology is no longer a futuristic idea—it is a practical solution for businesses looking to enhance productivity, reduce costs, and embrace sustainable practices. With Mart Laser, companies gain access to advanced systems, professional guidance, and a partner committed to innovation in industrial cleaning solutions. Upgrade your workflow, protect your assets, and achieve unparalleled efficiency with Mart Laser’s laser cleaning technology.