How Centrifugal Blower from Cbbmachine Shapes Directed Airflow

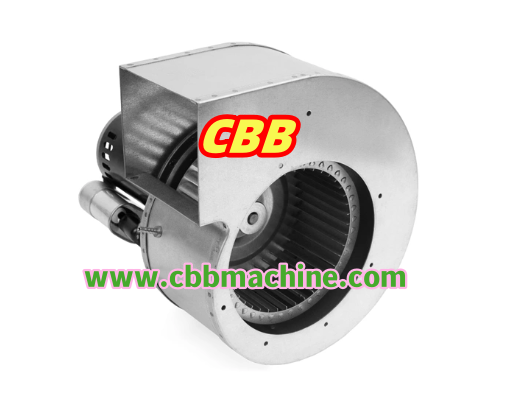

In many processing environments, the Centrifugal Blower from Cbbmachine enters early design discussions due to its role in shaping controlled air movement across multiple stages of production. Its structure guides air in a focused path, supporting processes that rely on steady drying, cooling, cleaning, or material separation. As modern lines incorporate more automation and closed-loop arrangements, directed airflow becomes essential for maintaining consistent conditions and protecting material quality.

A well-designed airflow system stabilizes the environment around sensitive substrates. When air moves in a steady stream rather than swirling unpredictably, coatings settle uniformly, temperature shifts remain manageable, and surfaces maintain their intended texture. This kind of predictable environment helps operators maintain clarity during tasks that require precise handling, particularly when working with specialty films, engineered papers, or bonded layers sensitive to moisture and heat.

Air movement also supports cleanliness in operations where particle reduction matters. By directing flow at defined angles, the blower assists in lifting dust or debris from working surfaces without disturbing the orientation of materials. Such controlled action aligns with the needs of industries that handle films, foils, or composite sheets where small contaminants can interfere with lamination, printing, or finishing.

Adaptability is another meaningful trait. A thoughtfully constructed blower fits into lines of varying scale, from compact converting stations to larger modular systems. When integrated with ducts, hoods, or diffusers, it contributes to a balanced flow pattern that complements machine layout. This coordination helps the wider system maintain rhythm by promoting consistent air distribution that neither overwhelms nor neglects key areas of the process.

Reliability further influences long-term planning. Blowers crafted with attention to component balance, internal geometry, and smooth rotational behavior typically sustain uniform output across repeated cycles. Their ability to maintain steady performance simplifies maintenance scheduling, supporting teams that depend on predictable operating characteristics to manage inspection intervals and equipment downtime.

When engineers introduce airflow elements into new or existing systems, they often assess how the blower interacts with thermal loads, material paths, and space constraints. A properly aligned configuration can enhance drying efficiency, reduce unwanted condensation, or create a stable environment for coating adhesion. By coordinating airflow with mechanical movements, the entire line gains a sense of coherence that allows each stage to operate with fewer interruptions.

As operations become increasingly data-aware, airflow stability contributes to clearer process feedback. Predictable patterns help operators interpret sensor readings and adjust settings with confidence. This synergy between mechanical action and environmental control supports a more transparent production cycle, easing the transition between shifts or product variations.

If the idea of shaping clean, intentional airflow sparks your interest, follow that impulse toward a corner of the web crafted for practical engineering insight. A quiet passage opens at https://www.cbbmachine.com/ .