Industrial Automation Market Trends: AI, IoT, and Industry 4.0 Driving Transformation

United States of America– 23 Dec 2025- Industrial automation systems integrate control technologies like robots, sensors, and software to streamline manufacturing processes. These solutions replace manual operations with precise, data-driven methods, boosting efficiency across sectors such as oil & gas, automotive, and food & beverages. As Industry 4.0 evolves, businesses leverage automation for smarter factories and resilient supply chains.

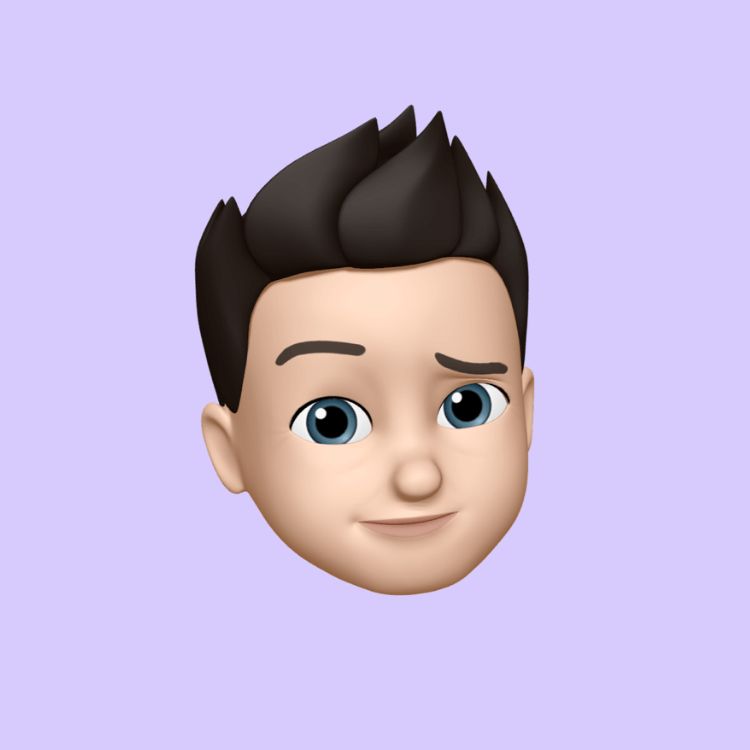

The industrial automation market size is projected to reach US$ 322.67 billion by 2030 from US$ 171.23 billion in 2022. The market is expected to register a CAGR of 8.2% during 2022–2030. The adoption of the Industry 4.0 concept is likely to remain a key trend in the market.

For more information- https://www.theinsightpartners.com/reports/industrial-automation-market

Key Drivers Fueling Growth

Convergence of IT and OT stands out as a primary force, enabling real-time visibility into operations. Manufacturers use connected devices and industrial IoT platforms to generate data for predictive analytics and anomaly detection. This integration supports faster decision-making and process optimization, reducing downtime effectively.

Government initiatives worldwide accelerate adoption by promoting productivity and safety. Programs like Germany's Industry 4.0, China's Made in China 2025, and India's Make in India provide incentives for advanced technologies. These efforts align with rising demands for personalized products, pushing firms toward automated solutions that deliver quality swiftly.

Download PDF Copy- https://www.theinsightpartners.com/sample/TIPRE00025985

Emerging Technologies Reshaping Operations

Artificial intelligence transforms machines into adaptive systems capable of learning and autonomous decisions. In industrial settings, AI powers robots for inspection, maintenance, and material handling, minimizing human involvement and accident risks. Prebuilt machine learning applications simplify deployment for operations teams via intuitive interfaces.

Immersive technologies like VR and AR enhance training and real-time collaboration. Workers access 3D instructions, remote assistance, and live data streams from IIoT sensors, streamlining repairs and assembly. These tools bridge skills gaps, foster closed-loop feedback, and improve overall performance in complex environments.

Machine vision paired with deep learning excels in quality control for electronics and automotive parts. Smart sensors detect defects early, ensuring high standards without constant oversight. Such advancements make automation scalable for diverse industries, from chemicals to aerospace.

United States of America– 23 Dec 2025- Industrial automation systems integrate control technologies like robots, sensors, and software to streamline manufacturing processes. These solutions replace manual operations with precise, data-driven methods, boosting efficiency across sectors such as oil & gas, automotive, and food & beverages. As Industry 4.0 evolves, businesses leverage automation for smarter factories and resilient supply chains.

The industrial automation market size is projected to reach US$ 322.67 billion by 2030 from US$ 171.23 billion in 2022. The market is expected to register a CAGR of 8.2% during 2022–2030. The adoption of the Industry 4.0 concept is likely to remain a key trend in the market.

For more information- https://www.theinsightpartners.com/reports/industrial-automation-market

Key Drivers Fueling Growth

Convergence of IT and OT stands out as a primary force, enabling real-time visibility into operations. Manufacturers use connected devices and industrial IoT platforms to generate data for predictive analytics and anomaly detection. This integration supports faster decision-making and process optimization, reducing downtime effectively.

Government initiatives worldwide accelerate adoption by promoting productivity and safety. Programs like Germany's Industry 4.0, China's Made in China 2025, and India's Make in India provide incentives for advanced technologies. These efforts align with rising demands for personalized products, pushing firms toward automated solutions that deliver quality swiftly.

Download PDF Copy- https://www.theinsightpartners.com/sample/TIPRE00025985

Emerging Technologies Reshaping Operations

Artificial intelligence transforms machines into adaptive systems capable of learning and autonomous decisions. In industrial settings, AI powers robots for inspection, maintenance, and material handling, minimizing human involvement and accident risks. Prebuilt machine learning applications simplify deployment for operations teams via intuitive interfaces.

Immersive technologies like VR and AR enhance training and real-time collaboration. Workers access 3D instructions, remote assistance, and live data streams from IIoT sensors, streamlining repairs and assembly. These tools bridge skills gaps, foster closed-loop feedback, and improve overall performance in complex environments.

Machine vision paired with deep learning excels in quality control for electronics and automotive parts. Smart sensors detect defects early, ensuring high standards without constant oversight. Such advancements make automation scalable for diverse industries, from chemicals to aerospace.

Industrial Automation Market Trends: AI, IoT, and Industry 4.0 Driving Transformation

United States of America– 23 Dec 2025- Industrial automation systems integrate control technologies like robots, sensors, and software to streamline manufacturing processes. These solutions replace manual operations with precise, data-driven methods, boosting efficiency across sectors such as oil & gas, automotive, and food & beverages. As Industry 4.0 evolves, businesses leverage automation for smarter factories and resilient supply chains.

The industrial automation market size is projected to reach US$ 322.67 billion by 2030 from US$ 171.23 billion in 2022. The market is expected to register a CAGR of 8.2% during 2022–2030. The adoption of the Industry 4.0 concept is likely to remain a key trend in the market.

For more information- https://www.theinsightpartners.com/reports/industrial-automation-market

Key Drivers Fueling Growth

Convergence of IT and OT stands out as a primary force, enabling real-time visibility into operations. Manufacturers use connected devices and industrial IoT platforms to generate data for predictive analytics and anomaly detection. This integration supports faster decision-making and process optimization, reducing downtime effectively.

Government initiatives worldwide accelerate adoption by promoting productivity and safety. Programs like Germany's Industry 4.0, China's Made in China 2025, and India's Make in India provide incentives for advanced technologies. These efforts align with rising demands for personalized products, pushing firms toward automated solutions that deliver quality swiftly.

Download PDF Copy- https://www.theinsightpartners.com/sample/TIPRE00025985

Emerging Technologies Reshaping Operations

Artificial intelligence transforms machines into adaptive systems capable of learning and autonomous decisions. In industrial settings, AI powers robots for inspection, maintenance, and material handling, minimizing human involvement and accident risks. Prebuilt machine learning applications simplify deployment for operations teams via intuitive interfaces.

Immersive technologies like VR and AR enhance training and real-time collaboration. Workers access 3D instructions, remote assistance, and live data streams from IIoT sensors, streamlining repairs and assembly. These tools bridge skills gaps, foster closed-loop feedback, and improve overall performance in complex environments.

Machine vision paired with deep learning excels in quality control for electronics and automotive parts. Smart sensors detect defects early, ensuring high standards without constant oversight. Such advancements make automation scalable for diverse industries, from chemicals to aerospace.

0 Reacties

0 aandelen

11 Views

0 voorbeeld